Unbalance-Motor-Problem

Mass Imbalance or Mechanical Imbalance

Not Voltage imbalance

Imbalance vs Unbalance

imbalance is the noun meaning the state of being not balanced, while unbalance is the verb meaning to cause the loss of balance.

What is Imbalance Problem?

Electric vehicles (EVs) can experience imbalance issues in their electric motors. similar to any rotating machinery. Imbalance occurs when the mass distribution of a rotating component is not uniform, causing uneven forces and vibrations

Imbalance is a condition of a rotating part where the center of mass does not lie on the axis of rotation. In other words, there is a “heavy spot” somewhere on the rotor. Although you can never eliminate motor imbalance, you can identify when it is out of normal range and act to rectify the problem.

Electric vehicles (EVs) can experience imbalance issues in their electric motors, similar to any rotating machinery. Imbalance occurs when the mass distribution of a rotating component is not uniform, causing uneven forces and vibrations.

Electric vehicles (EVs) can experience imbalance issues in their electric motors, similar to any rotating machinery. Imbalance occurs when the mass distribution of a rotating component is not uniform, causing uneven forces and vibrations. However, modern EV manufacturers design their motors with careful attention to balancing to minimize these problems.

Electric vehicles can experience imbalance problems in their electric motors. Some common issues include:

- Electrical imbalance: The three phases of the AC power supply may not be perfectly balanced, which can lead to torque ripple and vibration in the motor. This can reduce the motor's efficiency and performance.

- Magnetic imbalance: The magnetic poles or rotor in the motor may not be perfectly symmetric, which can also cause torque ripple and vibration. This can happen due to manufacturing tolerances or damage to the motor magnets over time.

- Mechanical imbalance: The motor shaft, rotor, or other rotating components may be uneven in weight distribution, causing vibration at certain speeds. This can put extra stress on motor bearings and reduce motor life.

- Thermal imbalance: Uneven heating inside the motor stator or rotor can cause localized hot spots, which impacts the magnetic fields and motor performance. This is more likely when the motor is under high loads.

Cause of Imbalance Problem

This is due to a number of factors, including:

- Improper manufacturing of the motor

- Damage to the motor from impact or other sources

- Degradation of the motor over time due to wear and tear

Imbalance can be caused by numerous factors, including:

- Dirt accumulation

- Missing balance weights

- Manufacturing variations

- Uneven mass in motor windings and other wear-related factors.

Electric motor imbalance can arise due to various factors, such as manufacturing tolerances, variations in component materials, or assembly errors. Imbalance in an electric motor can lead to increased vibrations, reduced performance, and potentially accelerated wear and tear on the motor and other associated components.

Electric motor imbalance can arise due to various factors, such as manufacturing tolerances, variations in component materials, or assembly errors. Imbalance in an electric motor can lead to increased vibrations, reduced performance, and potentially accelerated wear and tear on the motor and other associated components.

Symptoms of Imbalance Problem

Imbalance problems in an electric motor can cause a number of symptoms, including:

- Vibration

- Noise

- Reduced power output

- Reduced efficiency

- Increased wear and tear on other components

Ways to prevent Imbalance Problem

Ways to prevent imbalance problems in electric vehicle motors:

- Use high-quality motors that are manufactured to strict standards

- Inspect motors regularly for signs of damage

- Replace motors as soon as they show signs of wear and tear

- Use proper maintenance procedures

To mitigate these issues, EV manufacturers employ techniques such as precision manufacturing processes, dynamic balancing procedures, and quality control measures to minimize motor imbalances. Additionally, advanced motor control systems can detect and compensate for certain imbalances during operation, ensuring smoother and more efficient performance.

To mitigate these issues, EV manufacturers employ techniques such as precision manufacturing processes, dynamic balancing procedures, and quality control measures to minimize motor imbalances. Additionally, advanced motor control systems can detect and compensate for certain imbalances during operation, ensuring smoother and more efficient performance.

Some solutions to address imbalance issues in EV motors include:

- Improved motor design with tighter manufacturing tolerances.

- Weight balancing rotors and other spinning components.

- Active vibration control using sensors and actuators to cancel out imbalance forces.

- Improved cooling systems and thermal management to prevent uneven heating.

- Torque ripple minimization algorithms in the motor control software.

- Routine inspections and maintenance to detect imbalance problems early before major damage occurs.

Imbalance Motor Problem

Rotor Fault ⭢ Imbalance

bldc-fault

(rajagopalanDetectionRotorFaults2006, link, DOI, zolib)

The detection of faults in motors operating under constant speed conditions is straightforward because of the use of the well-known Fourier transformation [2]–[4]. However, the Fourier transformation cannot be directly applied to the analysis of nonstationary signals. This important limitation of the Fourier transformation raises the need for more sophisticated signal processing techniques for the analysis of nonstationary signals. Often, assumptions of local stationary operation may have to be made. Even under these assumptions, it is difficult to arrive at a solution that may be effective over a wide range of operating conditions and faults.

There has been little research in the area of fault diagnostics of motors operating under nonstationary conditions, and what has been reported is limited to induction motor applications. In one such method, the short time Fourier transforms (STFTs) and statistical methods are used to detect broken bar and bearing defects from the induction motor stator current in applications where the motor speed and load are time dependent. However, this algorithm is based on the assumption that the changes in speed and load occur slowly, and there are sufficient intervals of time where the motor can be assumed to operate in a stationary condition [5]. Wavelet packet transforms and artificial neural networks have also been applied to detect motor faults in similar applications [6].

(yanRotorUnbalanceFault2019, link, DOI, zolib)

(meyMachineLearningBasedUnbalance2020, link, DOI, zolib)

For example, the analysis of vibrations on rotating shafts to detect unbalances or to detect damage to roller bearings has proven to be very promising [19]–[27].

Mass unbalance is one of the common problems associated with motor vibration. Unbalanced masses in the rotating parts create a centrifugal force that causes the unit to vibrate. Mass unbalance occurs when the geometric centre (shaft centreline) and the mass centre of a rotor do not coincide. Unbalance is a once-per-revolution fault - that is, it occurs at the frequency of rotor speed and is sometimes difficult to distinguish from misalignment. Mass unbalance has a fixed phase angle with respect to a reference mark on the shaft. It will appear at 1 st order running speed where it affects the relative magnitude of the horizontal-to-vertical components.

Paper

(gucluVibrationAnalysisInduction2017, link, DOI, zolib)

Mechanical faults of induction motors, such as rotor imbalance and misalignment of the shaft, are most common problems. In most applications, it is important to notice that these mechanical faults affect the safety and/or efficiency of working environment [2], [3]. Mechanical faults may cause torque oscillations and/or eccentricity faults. Torque oscillations may be caused by unbalanced loading, shaft misalignment, gearbox faults and bearing related faults. An eccentricity fault is a nonuniform air gap which may be caused by bearing wear or bearing failure, and bad motor assembly with unbalanced or noncentral rotor [4]–[7]. Eccentricity faults as shown in Fig. 2, are classified into three groups: static eccentricity (SE), dynamic eccentricity (DE) and mixed eccentricity (ME) [4], [7], [8].

Paper

(gopinathStudyElectricMotor2010, link, DOI, zolib)

Mass unbalance is one of the common problems associated with motor vibration.

Unbalanced masses in the rotating parts create a centrifugal force that causes the unit to vibrate.

Mass unbalance occurs when the geometric centre (shaft centreline) and the mass centre of a rotor do not coincide. Unbalance is a once-per-revolution fault-that is, it occurs at the frequency of rotor speed and is sometimes difficult to distinguish from misalignment. Mass unbalance has a fixed phase angle with respect to a reference mark on the shaft. It will appear at 1st order running speed where it affects the relative magnitude of the horizontal-to-vertical components.

Paper

(hangFaultDiagnosisMechanical2013, link, DOI, zolib)

Furthermore, FFT is not suitable for the non-stationary state [11]–[14]. Time-frequency analysis methods have been applied to feature extraction for nonstationary signal [11]–[14], [20] and wavelet transform is a very suitable approach to detect electrical motor faults in a nonstationary state and solves these problems by decomposing a time series into time/frequency space simultaneously. Discrete wavelet transform (DWT) has been successfully applied to detect the faults in electrical motors under non-stationary condition [21]–[23]. Nevertheless, few published documents have discussed two problems at the same time, namely removing the dominant fundamental component and extracting fault feature under nonstationary condition.

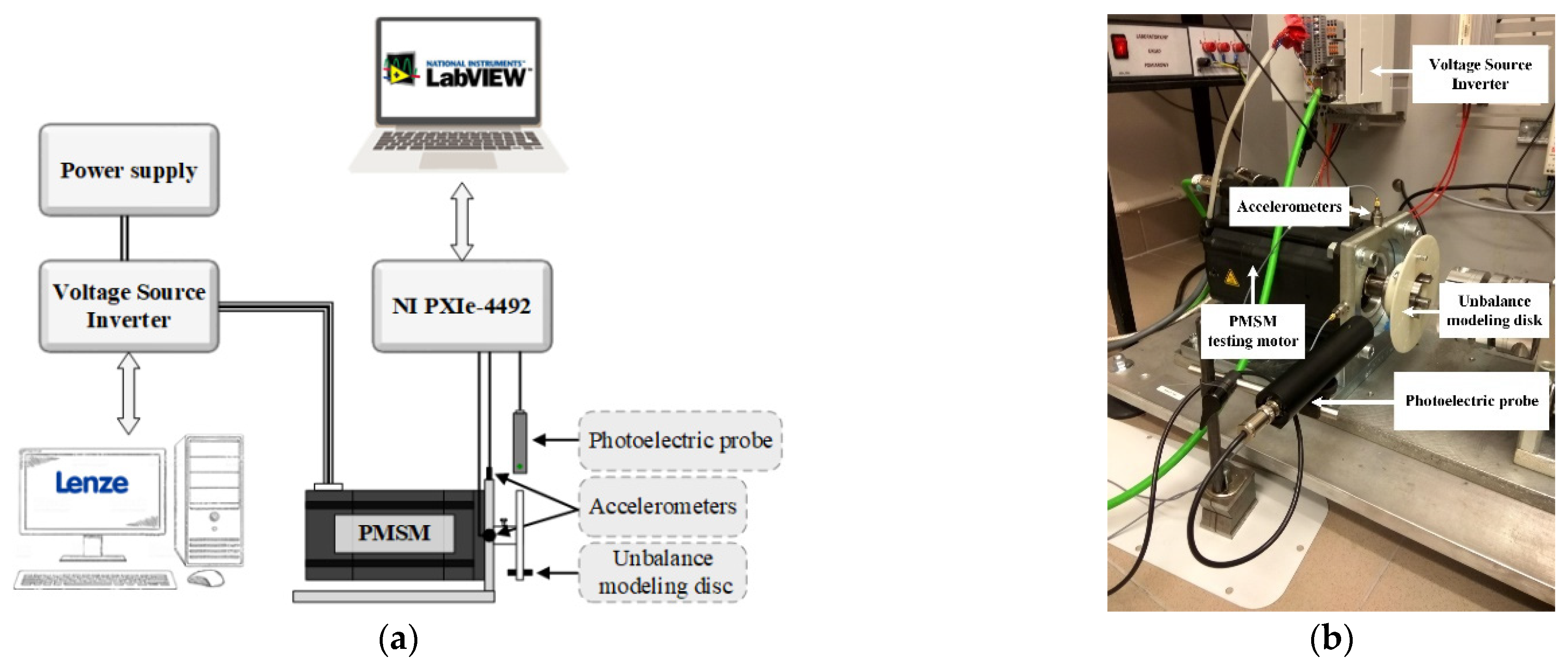

A PMSM drive system with a mechanical unbalance fault can be modeled as shown in Figure 1. It can be seen that the mechanical unbalance of the PMSM drive system is simulated by a mass of total unbalance m. Gravity force (mg) is generated by the unbalance mass m and the acceleration of gravity g, which can be decomposed into two parts: mgcosθ and mgsinθ in this reference frame and the latter produces a torque to the opposite direction of rotation, where it is assumed that the mechanical system with unbalance fault is horizontally installed along its rotational axis and the load torque is a function of the mechanical rotor position θ.

For the sake of clarity, higher order components are neglected, and only the fundamental component is considered. Hence, load torque Tload can be described by a constant component Tconst and an additional component caused by the unbalance fault, which is given as follows

Tload=Tconst+mgrsinθ=Tconst+Tusin(ωrt)(1)

View Source![]() where Tu=mgr is the amplitude of torque oscillation produced by the mechanical unbalance fault. ωr is the mechanical rotor speed and ωr=2πfr.fr is the mechanical rotor frequency of PMSM. To the purpose of quantitative evaluation of the mechanical unbalance degree of PMSM, an unbalance factor is defined as

where Tu=mgr is the amplitude of torque oscillation produced by the mechanical unbalance fault. ωr is the mechanical rotor speed and ωr=2πfr.fr is the mechanical rotor frequency of PMSM. To the purpose of quantitative evaluation of the mechanical unbalance degree of PMSM, an unbalance factor is defined as

FT=(Tu/Tconst)×100%

Speed Waveform

Paper

(rafaqSimpleMethodIdentifying2022, link, DOI, zolib)

Faults in the PMSM rotor, such as rotor eccentricity or demagnetization, or defects in the load, such as mass unbalance or misalignment, degrade motor performance and reliability. These defects in the rotor or load can lead to undesirable vibration that accelerates the degradation of motor components causing premature failure of the motor and driven system.

Vibration analysis (VA), where the frequency spectrum of the vibration signal is analyzed [1]–[4], [14]–[17], is considered the most common and reliable means of detecting mechanical faults in rotating machines. It is well known that most defects in the rotor or load produce vibration once per rotor revolution (1×) at the rotor rotational frequency fr given as [6], [8]

fr= k⋅fs/p(1)

where fs and p are the source frequency and the number of pole pairs, respectively, and k represents the vibration at integer multiples of fs/p. An increase in the fr component can be observed for the load faults, such as mass unbalance, misalignment, and PMSM rotor faults, such as asymmetric PM demagnetization and rotor eccentricity [14]–[17].

Since any type of fault in the rotating component produces identical fr-related components with VA or MCSA, the type of fault cannot be identified [5], [6]. A number of methods for classifying the type of fault have been studied [5]–[7]. However, offline methods are not capable of detecting the load defects [5], and the methods that rely on the mathematical model [6] or high-frequency signal injection [7] are prone to modeling errors or are invasive. This is a serious limitation since some faults require immediate repair or replacement, whereas others can wait till the next outage for a simple adjustment. There is a lot of value in identifying the type of fault since any information regarding the fault could help determine the course of action and improve the reliability and availability of the PMSM system. Another problem of MCSA is that the detectability and sensitivity of the fault detection depend on the motor and controller design [11]. In this work, a simple method for identifying mass unbalance from the vibration measurement commonly available is proposed. The theory and experimental study shows that analyzing the speed dependence of vibration can be used for identifying mass unbalance from other faults that produce the fr-related components with VA or MCSA.

Among the numerous mechanical faults or defects that cause vibration problems in rotating systems, mass unbalance is known as one of the most common root causes. It is estimated in [14] that mass unbalance accounts for 40% of all vibration problems. Rotating unbalance causes harmful vibration and noise at fr that accelerates the wear of insulation, bearings, couplings, and other components with mechanical contact points. The life expectancy of the machine and its components is significantly reduced with an increase in mass unbalance.

Mass unbalance is a condition where the center of mass cm of the rotating object is not coincident with the geometric center cg (center of rotation), as shown in Fig. 1. This can be caused by nonuniform distribution of mass, manufacturing imperfections or tolerances, or gain/loss of material during operation or maintenance, etc. It is equivalent to have an imaginary heavy spot at one location, as shown in Fig. 1. The centrifugal force Fc on the rotor due to the heavy spot is given as

Fc= mrω2(3)

where m and r are the mass and radius of the heavy spot, and ω is the speed of rotation. The centrifugal force pulls the rotor upward or downward at the locations, as shown in Fig. 1(a) and (b), respectively, and this causes the once per revolution (1×) periodic vibration at fr [14]–[16]. The gravitational force Fg of 9.8 N acts in the direction of gravity for both cases and does not influence the net vibration. Equation (3) shows that the vibratory force is proportional to the square of the rotor speed if it is caused by mass unbalance. The heavy spot can be detected by placing the rotating object on a balancing machine. When mass unbalance is detected, an object of equal weight is placed on the opposite side (180° apart at the same r), as shown in Fig. 1(c), for compensation to prevent vibration [14]–[17].

A rotor with dynamic eccentricity can also include mass unbalance and has a small speed-dependent increase in vibration but it is small, considering the small airgap. In addition, mass unbalance and dynamic eccentricity are independent, and a rotor with inherent dynamic eccentricity will be well balanced after the post manufacturing balancing operation. Misalignment between the motor and load is also a leading cause of problems that lead to fr dependent vibration. It is caused by the periodic strain between the motor and load shafts and is insensitive to speed changes. There are also other root causes of fr vibration, such as mechanical looseness, soft foot, load eccentricity, and coupling or bearing problems [14]–[17], but the magnitude of vibration is known to be insensitive to the speed [14]. The simple idea of monitoring the speed dependence of vibration can be used as an effective means of identifying mass unbalance among all the rotor and load faults that produce the fr or _f_fault components with VA or MCSA.

Other Paper

(fournierCurrentBasedDetectionMechanical2015, link, DOI, zolib)

(ewertComparisonEffectivenessSelected2022, link, DOI, zolib)

(obaidEffectLoadDetecting2003, link, DOI, zolib)

(imamuraDiagnosisUnbalanceLightweight2022, link, DOI, zolib)

Unbalance can be expressed in terms of an equivalent mass m with an eccentricity e, it is usually given as the product m⋅e�⋅�:

Feq=m⋅e∗ω2sin(ωt−θ)���=�⋅�∗�2sin(��−�)

(5)

where ω is the angular velocity and Feq��� is the resulting unbalanced force acting on the system (ISO 13373-1:2018). There are three prevalent unbalance types: static, coupled, and dynamic. This classification considers the relative position between the axis of rotation and mass.

(corneMisalignmentUnbalanceFault2017, link, DOI, zolib)

Due to imperfections, any operating IM is always severing mechanical unbalance due to mass-eccentricity. Figure 6 presents the definition of an eccentric mass. Aside the geometric position of the rotor, once the gravitational center-point of the rotor deviates from the rotational center, mass-eccentricity can be defined. The quantification of the unbalance is done by defining a certain equivalent mass-unbalance, munb,eq, and a gravitational radius of that mass, runb. By coupling direct loads onto the shaft of the machine (e.g. pulleys, gears, sprockets), the unbalance is increased insuperable. Unbalance is fairly easy to identify by vibration analysis, because the eccentric mass generates an alternating force on the bearings and so on the stator housing (proportional with the measured acceleration). In order to detect the mass-unbalance in the stator current, an air gap variation must be imposed between the stator and the rotor. That variation is generally induced by the unbalance force reacting onto the bearings, as they act as a simplified spring-system. The specific stiffness of the spring-system can be provided by the bearing-supplier. The result of the propagation of the unbalanced force on the bearings is in fact a classic example of dynamic eccentricity (see Figure 1, right). Therefore, in a first approach, mass-eccentricity will be emulated by applying a dynamic eccentricity onto the machine.

As the unbalance induces a dynamic eccentricity, the specific rotor-movements dx and dy are obtained by following time-based trigonometric formulas:

dx=Aunb⋅sin(2⋅π⋅fr⋅t)dy=Aunb⋅sin(2⋅π⋅fr⋅t+π2)(8)(9)

Now, the only unknown parameter in obtaining the rotor-movements for every mass-unbalance is the magnitude of the dynamic eccentricity, Aunb. As the dynamic eccentricity is induced due to the centrifugal force originated by the mass-unbalance, it can be calculated as follows:

Aunb=Funbkrad,DE=4⋅π2⋅muΠeq⋅ru‡1⋅f2rkrad,DE(10)

Paper

(dioufUnderstandingRotorBalance2014, link, DOI, zolib)

ChatGPT

In the context of permanent magnet electric motors, an imbalance or unbalance fault refers to a condition where the rotor experiences an uneven distribution of mass or magnetic flux. This fault can result in undesirable effects on the motor's performance and efficiency.

Several causes can contribute to an imbalance or unbalance fault in a permanent magnet electric motor. These include:

- Manufacturing defects: Inaccurate or imprecise manufacturing processes can lead to uneven distribution of mass or magnetic flux in the rotor, resulting in an inherent imbalance.

- Mechanical wear and tear: Over time, various components of the motor, such as bearings or rotor windings, may degrade or suffer damage. This can lead to imbalances due to misalignment or distortion of the rotor.

- Assembly errors: Improper assembly of the motor, such as incorrect positioning of the magnets or misalignment of the rotor with respect to the stator, can introduce imbalances.

- External factors: Environmental conditions, such as excessive vibrations, shocks, or thermal stress, can affect the integrity of the motor's components and contribute to an imbalance fault.

Bard

An imbalance fault in a permanent magnet electric motor is a condition in which the weight distribution of the rotor is not evenly distributed.